- How Computer Vision Works in Manufacturing Environments

- 8 Computer Vision Solutions Transforming the Manufacturing Industry

- 1. Automated defect detection and classification

- 2. Dimensional and measurement verification

- 3. Assembly verification and component presence detection

- 4. Surface quality inspection

- 5. OCR and label verification

- 6. Robotic guidance and bin picking

- 7. Predictive maintenance through visual inspection

- 8. Quality analytics and process optimization

- Computer vision applications: Quick comparison

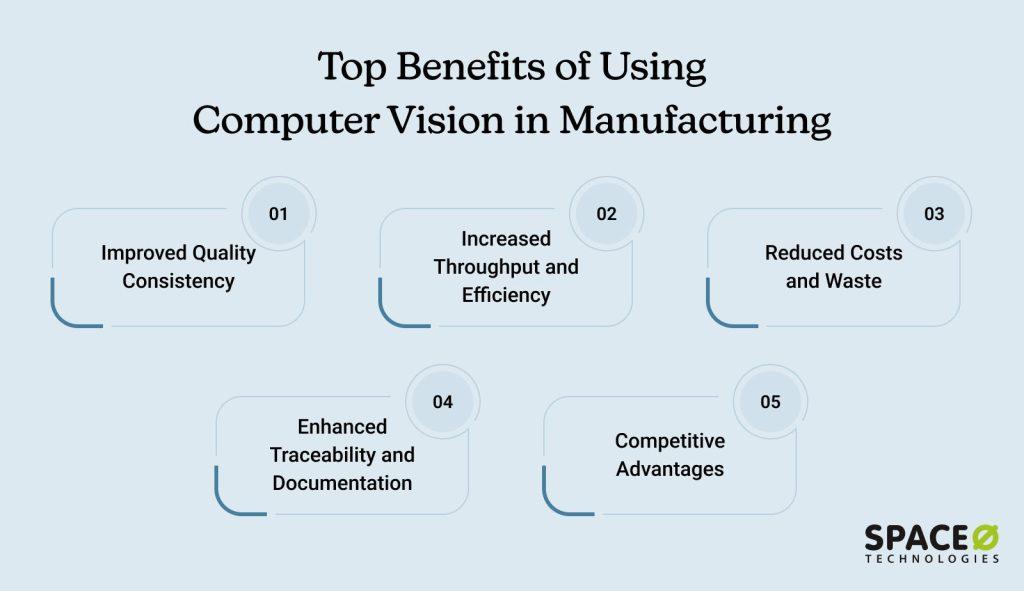

- Key Benefits of Computer Vision Solutions for Manufacturing

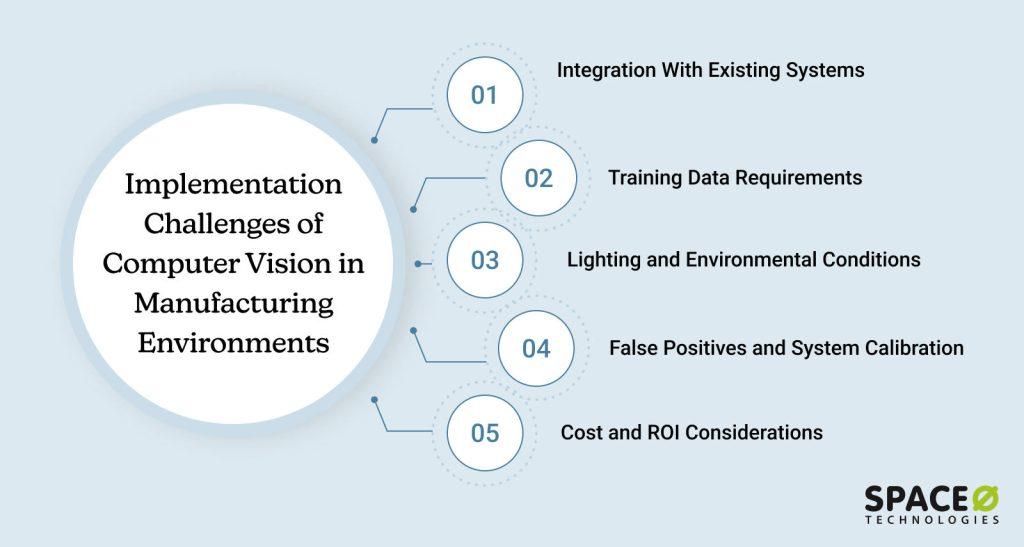

- Common Challenges When Implementing Computer Vision in Manufacturing

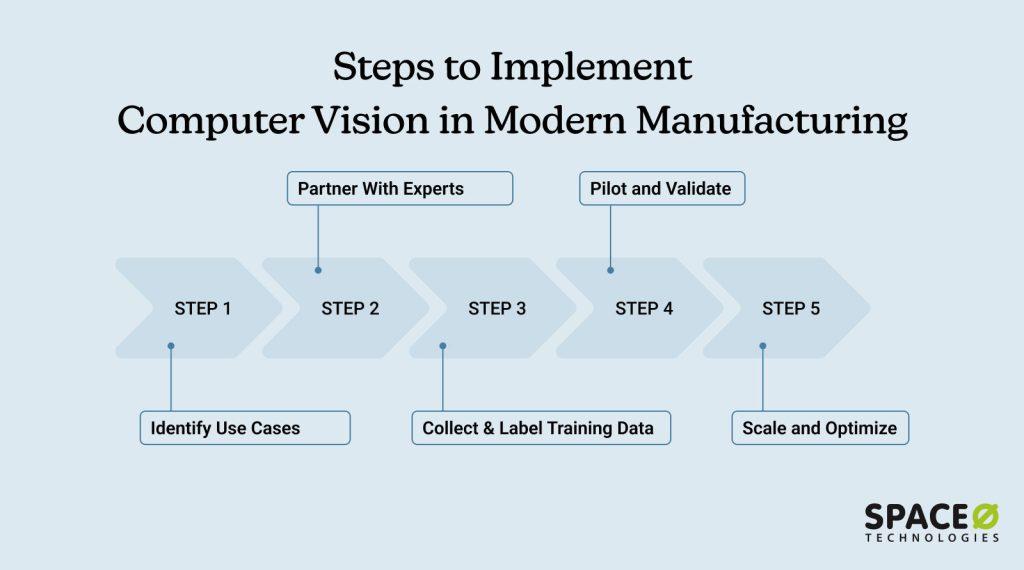

- How to Implement Computer Vision in Your Manufacturing Operations

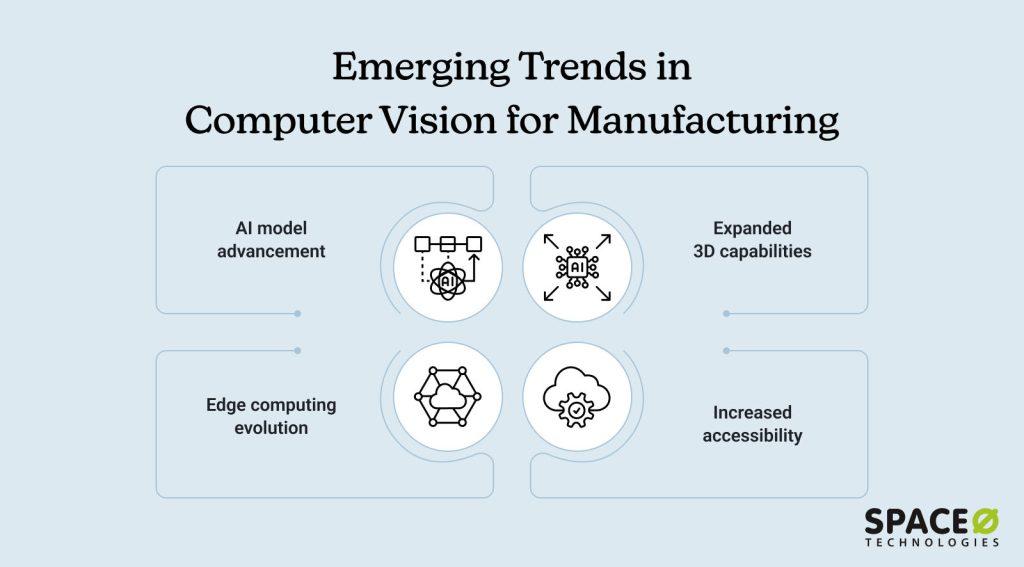

- Future Trends in Computer Vision for Manufacturing

- Streamline Your Manufacturing Operations with Custom Computer Vision Solution Development

- Frequently Asked Questions on Manufacturing Computer Vision Solutions

- How accurate are computer vision systems compared to human inspectors?

- What’s the typical ROI timeline for computer vision implementation?

- Can computer vision systems work with our existing equipment and processes?

- How much training data is required for effective defect detection?

- What maintenance do computer vision systems require?

- Can we implement computer vision without disrupting current production?

Computer Vision Solutions for Manufacturing: Applications, Benefits & Challenges

Manufacturers today face growing pressure to improve efficiency, quality, and safety, while keeping costs low and meeting rising customer expectations. But traditional manual inspection and process control methods often fall short in achieving these goals.

According to ETQ, 75% of manufacturers experienced at least one product recall in the past five years, with nearly half reporting costs between $10 million and $50 million per recall. Every defect that reaches customers damages brand reputation and erodes customer trust.

That’s where computer vision is making a major impact. By enabling machines to “see,” analyze, and interpret visual data from cameras and sensors, computer vision brings automation, precision, and intelligence to every stage of manufacturing.

This goes from raw material inspection to assembly line monitoring and predictive maintenance. As a leading manufacturing AI solutions development company, we often see manufacturers struggle with challenges like inconsistent quality checks, unplanned downtime, and limited process visibility. These are the challenges that computer vision can easily solve.

In this blog, we’ll explore how computer vision is transforming manufacturing operations, its key applications, benefits, and implementation challenges. Learn how your business can leverage it to build a smarter, more efficient production ecosystem.

How Computer Vision Works in Manufacturing Environments

Computer vision systems process visual data through four distinct stages, each playing a critical role in identifying defects and ensuring quality.

1. Image capture

Specialized cameras and sensors capture product images at precise moments during production. The timing is crucial. High-resolution cameras photograph products as they pass inspection stations, often using multiple angles and wavelengths of light to reveal different defect types that might be invisible to standard photography.

2. Image preprocessing

Raw images get cleaned up before analysis. The system adjusts brightness, removes background noise, and normalizes images for consistent quality. This ensures the AI model receives standardized input regardless of lighting conditions, product positioning, or environmental factors that could affect image quality.

3. AI analysis and decision-making

Deep learning models analyze processed images using convolutional neural networks (CNNs). These networks compare current products against thousands of training examples. The system assigns confidence scores to its findings and flags products that fall below quality thresholds, making split-second decisions about pass or fail.

4. Real-time action and feedback

Integration with manufacturing execution systems closes the loop. When defects are detected, the system immediately triggers actions: removing defective products from the line, alerting quality operators, or adjusting machine parameters. This real-time response prevents defective products from advancing through production stages.

Pro Tip: Invest in proper lighting design for your inspection stations. Even the best AI models struggle with poorly illuminated images. Work with computer vision developers who understand industrial lighting requirements.

Now, let’s take a look at some of the key applications of computer vision in manufacturing.

8 Computer Vision Solutions Transforming the Manufacturing Industry

To see how computer vision is driving the factory of the future, explore these eight proven applications. These solutions are actively transforming quality control and boosting operational efficiency across the industry.

1. Automated defect detection and classification

Computer vision technology identifies defects that human inspectors miss at speeds matching the fastest assembly lines. The technology detects scratches, dents, cracks, and discoloration, inspecting every product without fatigue.

How advanced systems categorize defect

- Type: Scratch, crack, dent, discoloration, or contamination

- Severity: Minor cosmetic issue or critical quality failure

- Location: Precise coordinates on the product surface

Real-world applications

- Electronics manufacturers catch micro-cracks in circuit boards

- Automotive suppliers identify sub-millimeter paint defects

- Pharmaceutical companies verify tablet integrity at high speeds

Pro Tip: Include examples of acceptable variations when training defect detection models. This helps AI distinguish between cosmetic imperfections you’ll accept and quality defects you won’t, reducing false positives.

2. Dimensional and measurement verification

Vision systems measure multiple dimensions simultaneously, verifying components fall within tolerance ranges faster than traditional coordinate measuring machines. The technology achieves micron-level accuracy while handling in-line measurement for complete production runs.

What vision systems measure

- Length, width, height, and diameter

- Hole positions and diameters

- Thread dimensions and pitch

- Complex 3D profiles and geometries

Real-world applications

- Automotive manufacturers verify engine components where tolerances affect performance

- Aerospace suppliers check critical safety components with extreme precision

- Medical device manufacturers confirm implants match exact patient safety requirements

3. Assembly verification and component presence detection

Missing components and incorrect assembly cause product failures, warranty claims, and safety recalls. Computer vision confirms all required parts are present and correctly positioned in real-time, preventing defective assemblies from progressing through expensive downstream operations.

The technology acts as a digital checklist, verifying each assembly step before the product moves to the next station.

What systems verify

- Component presence and absence

- Correct part numbers and variants

- Proper orientation and positioning

- Reversed or inverted parts

Real-world applications

- Electronics manufacturers verify circuit board assembly with dozens of tiny components

- Automotive suppliers confirm engine assemblies contain all fasteners and sensors

- Appliance manufacturers check that control panels have the correct button configurations

4. Surface quality inspection

Vision systems detect surface defects, including scratches, scuffs, dents, color inconsistency, and uneven coating thickness. Advanced systems analyze surface topology in three dimensions using structured light or laser scanning to reveal defects that photographs might miss.

Common surface defects detected

- Scratches, scuffs, and abrasions

- Dents and depressions

- Color inconsistency and streaking

- Foreign material contamination

- Uneven coating thickness

Industry applications

- Automotive manufacturers inspect painted body panels for finish quality

- Appliance producers verify stainless steel finishes maintain coating uniformity

- Furniture manufacturers check wood veneer for color consistency and grain pattern matching

5. OCR and label verification

Computer vision uses optical character recognition to verify that products carry correct labels, lot codes, expiration dates, and serial numbers. This prevents shipping errors, ensures regulatory compliance, and maintains accurate product traceability throughout the supply chain.

What systems read and verify

- 1D and 2D barcodes

- Printed text against specifications

- Date codes matching production records

- Proper label positioning and orientation

Real-world applications

- Pharmaceutical companies verify that drug packaging contains correct dosage information and expiration dates

- Food manufacturers confirm lot codes and allergen warnings meet regulatory requirements

- Electronics producers validate serial numbers for warranty tracking and recall management

Pro Tip: Implement label verification immediately after printing. It’s easier and cheaper to relabel a component than to disassemble and relabel a finished product.

6. Robotic guidance and bin picking

Vision-guided robotics enables robots to adapt to variable conditions rather than following fixed paths. Cameras capture work area images, AI algorithms calculate object positions in 3D space, and robots generate real-time motion paths.

This flexibility becomes critical for bin picking, where parts arrive in random positions and orientations. Unlike fixed-position picking, bin picking requires the vision system to locate and retrieve randomly positioned parts from containers without manual organization.

How bin picking works

- Recognize parts regardless of position or orientation

- Calculate 3D coordinates in cluttered bins

- Plan collision-free paths to grasp targets

- Adapt grip strategies based on part orientation

- Achieve high success rates consistently

Industry applications

- Automotive suppliers pick engine components from bulk bins for assembly line feeding

- E-commerce warehouses pack randomly oriented products into shipping containers

- Machine shops load CNC machines with workpieces based on actual position variations

7. Predictive maintenance through visual inspection

Computer vision monitors equipment condition continuously, detecting early warning signs before failures occur. This predictive approach shifts maintenance from reactive emergency repairs to proactive scheduled interventions, maximizing uptime and reducing overall maintenance costs while preventing unexpected production disruptions.

What visual indicator systems monitor

- Lubricant levels and color changes

- Vibration patterns through motion analysis

- Oil leaks and fluid accumulation

- Belt wear, alignment, and tension

- Abnormal heat patterns with thermal imaging

Real-world applications

- Automotive plants monitor conveyor belt condition across miles of production lines

- Food processing facilities detect bearing wear in packaging equipment before catastrophic failure

- Chemical manufacturers identify pump seal degradation through early leak detection

8. Quality analytics and process optimization

Vision systems capture detailed defect information during every inspection, creating comprehensive quality databases. This data includes defect types, precise locations on products, frequency patterns over time, and correlations with specific machines, operators, or production shifts.

These insights transform raw inspection data into actionable intelligence for continuous improvement. Making sense of quality data requires visualization. Manufacturers use specialized software to analyze patterns and trends that would be invisible in raw data tables.

How visualization tools reveal insights

- Heat maps: Show where defects cluster on products

- Time-series charts: Reveal when defect rates increase

- Correlation analysis: Identify which parameters influence quality

- Trend tracking: Monitor improvement from process changes

Real-world applications

- Electronics manufacturers identify specific SMT machines producing solder defects

- Automotive suppliers correlate paint defects with environmental conditions in spray booths

- Packaging companies optimize line speeds by analyzing defect patterns across production shifts

Computer vision applications: Quick comparison

Here’s a quick comparison of the popular computer vision applications in manufacturing:

| Application | Primary Benefit | Best For |

|---|---|---|

| Defect Detection | Catch microscopic flaws | High-volume production |

| Dimensional Verification | Ensure precision | Automotive, Aerospace |

| Assembly Verification | Prevent missing parts | Electronics, Automotive |

| Surface Quality | Maintain aesthetics | Consumer goods, Automotive |

| Label Verification | Ensure compliance | Food, Pharmaceutical |

| Robotic Guidance | Enable flexibility | Mixed production lines |

| Predictive Maintenance | Reduce downtime | All manufacturing |

| Quality Analytics | Drive improvement | All manufacturing |

Overall, computer vision is a key technology in the manufacturing sector, with wide applications. Next, let’s explore the benefits of implementing computer vision technology in manufacturing.

See What Computer Vision Can Do for Your Factory

From defect detection to predictive maintenance, Space-O AI helps manufacturers bring these real-world use cases to life. Our custom-built computer vision solutions are designed to enhance precision, minimize waste, and accelerate production efficiency.Key Benefits of Computer Vision Solutions for Manufacturing

Computer vision technology doesn’t just improve operations; it delivers measurable ROI. Here are the key benefits manufacturers realize across quality, efficiency, and cost reduction.

1. Improved quality consistency

Solutions powered by computer vision technology eliminate human inspection variability by delivering identical evaluation standards for every product. Unlike human inspectors who experience fatigue, apply subjective judgment, or vary in experience levels, vision systems maintain peak accuracy across continuous operations.

This consistency builds customer confidence while providing the documented quality criteria needed to support certifications and compliance requirements.

2. Increased throughput and efficiency

Vision systems inspect at line speed without creating bottlenecks in your production flow. While human inspectors typically sample a percentage of production, computer vision solutions evaluate every single product that passes through the line.

A single system can handle inspection tasks that would otherwise require multiple inspectors working across different shifts. This frees your human workers to focus on higher-value activities like problem-solving and process improvement initiatives.

3. Reduced costs and waste

Computer vision solutions minimize costs by catching defects at the optimal time. Defects detected during manufacturing cost pennies to correct, while post-assembly corrections require expensive disassembly and rework.

When defects reach customers, warranty claims and recalls can cost thousands per incident. Manufacturers typically achieve rapid ROI through combined savings in scrap reduction, eliminated rework, fewer warranty claims, and lower inspection labor.

4. Enhanced traceability and documentation

Computer vision solutions create comprehensive quality records for every inspected product. The system stores images, measurements, and decisions tagged with unique identifiers that support recall management, warranty analysis, and compliance reporting.

This documentation accelerates root cause analysis by providing exact evidence of when and where defects occurred.

5. Competitive advantage

Computer vision solutions deliver multiple market advantages. The consistent quality builds customer confidence and strengthens brand reputation. Real-time feedback enables faster response to quality issues before they impact production.

The detailed process data from these systems enables continuous optimization that manual inspection cannot provide. These capabilities support mass customization and just-in-time manufacturing that would be impractical with traditional quality control. Investing in computer vision consulting services can help you identify which competitive advantages are most achievable for your specific operations.

These were some of the most striking benefits of investing in computer vision solutions for manufacturing. Now, it’s time we also look at some of the common challenges you might face during their implementation.

Common Challenges When Implementing Computer Vision in Manufacturing

While the advantages of computer vision are significant, successful deployment involves navigating specific technical and environmental challenges. Here’s an overview of the most common implementation hurdles and how to proactively address them.

1. Integration with existing systems

The problem

Vision systems must integrate with MES, quality management systems, and ERP platforms to ensure inspection data flows where needed. Legacy systems lacking modern APIs complicate integration, while large image files require substantial bandwidth that can overwhelm network infrastructure.

The solution

Computer vision development services by expert agencies like Space-O AI address integration challenges through middleware that bridges legacy systems, custom APIs that enable seamless data exchange, and edge computing solutions that process data locally before transmission. This approach ensures vision systems communicate reliably with existing infrastructure while maintaining flexibility for future technology evolution.

2. Training data requirements

The problem

Machine learning models require labeled images showing both acceptable products and various defect types. Simple applications need hundreds of images while complex inspections benefit from thousands of examples. Collecting sufficient training data challenges manufacturers when launching new products or lacking historical defect examples.

The solution

Transfer learning significantly reduces data requirements by adapting pre-trained models to specific applications, sometimes enabling deployment with just a few hundred application-specific images. Synthetic data generation creates artificial defect examples when real-world data is limited, while data augmentation techniques expand limited datasets through rotation, scaling, and brightness adjustments.

3. Lighting and environmental conditions

The problem

Vision performance depends on consistent, appropriate lighting. Shadows, glare, and ambient light variations degrade accuracy and inspection reliability. Industrial environments present challenging conditions with changing overhead lighting, variable natural light from windows, and reflective surfaces creating glare. Environmental factors like dust, vibration, temperature extremes, and moisture further impact system reliability.

The solution

Specialized illumination techniques reveal specific defect types: backlighting highlights edges and holes, diffuse lighting minimizes shadows and glare, structured lighting reveals surface topology, and dark-field lighting emphasizes scratches.

Industrial-grade vision components with proper IP-rated enclosures protect systems from harsh manufacturing environments while maintaining reliable operation across temperature ranges and vibration levels.

4. Positives and system calibration

The problem

No inspection system is perfect. False positives flag good products as defective, wasting time in secondary inspection and potentially reducing yields. False negatives pass defective products, defeating the purpose of automated inspection. Balancing these error types requires careful system calibration, where inspection sensitivity thresholds directly impact both error rates.

The solution

Computer vision developers work with quality teams to set appropriate thresholds based on business impact, weighing the cost of each error type against your specific quality requirements. Systems improve accuracy through continuous learning as operators review decisions and provide feedback. Models retrain on expanded datasets, adapting to process changes, new materials, and product variations while reducing error rates over time.

5. Cost and ROI considerations

The problem

Computer vision systems require capital investment, including cameras, lighting, computing platforms, software licenses, integration work, and implementation services. Hardware costs vary based on resolution and speed requirements, while software and development costs depend on application complexity. Implementation includes installation, operator training, and production disruption during deployment.

The solution

Phased implementation reduces upfront investment and risk by starting with a single high-impact application that demonstrates clear value. Most manufacturers achieve rapid ROI through hard savings in reduced scrap, lower rework costs, decreased warranty claims, and reduced inspection labor.

Use lessons learned from initial deployment to refine subsequent installations across additional lines and facilities, building organizational confidence while spreading investment over time.

Moving forward, let’s take a quick look at the best practices to follow when implementing computer vision solutions in your manufacturing operations.

Transform Your Manufacturing Operations with Computer Vision

Partner with Space-O AI to integrate computer vision into your manufacturing processes. From real-time defect detection to automated quality control, we help you unlock new levels of efficiency and precision.How to Implement Computer Vision in Your Manufacturing Operations

Integrating computer vision effectively demands a structured roadmap. Here are the five essential steps to guide your deployment, from initial concept to achieving production scale and maximizing quality improvements.

Step 1: Identify high-impact use cases

- Review quality data to identify products with high defect rates, operations with excessive scrap, and areas where manual inspection creates bottlenecks.

- Evaluate use cases based on frequency and cost of issues, production volume, defect complexity, and infrastructure needs.

- Engage stakeholders across quality, production, and maintenance for comprehensive input.

- You can work with an experienced computer vision consulting agency for expert guidence, use case discovery, and implementation roadmap.

Step 2: Partner with experienced computer vision developers

- Work with the team of experienced developers who understand both technology and manufacturing.

- Evaluate partners based on relevant experience, technical capabilities, and methodology. Request references and review case studies demonstrating success with matching applications. The partnership includes requirements definition, risk management, and knowledge transfer.

Step 3: Collect and label training data

- Start collecting representative images early, using lighting and perspectives that match the final installation.

- Quality engineers should label defects precisely, including edge cases that help models learn decision boundaries.

- Data augmentation and synthetic generation expand limited datasets.

Pro Tip: Establish clear acceptance criteria before data collection. Document what constitutes defects versus acceptable variation for consistent labeling.

Step 4: Pilot and validate

- Deploy systems in pilot mode parallel to the existing inspection.

- Define success metrics, including target accuracy rates, acceptable error rates, throughput requirements, and integration verification.

- Track performance throughout the pilot, revealing practical considerations before production transition.

Step 5: Scale and Optimize

- Expand across additional lines and facilities after successful validation.

- Each deployment benefits from lessons learned.

- Monitor accuracy metrics continuously, retrain models periodically, and expand to new applications like dimensional verification and predictive maintenance.

Computer vision implementation roadmap

Below is a quick overview of the essential phases and timelines for implementing a computer vision solution in your facility:

| Phase | Key Activities | Duration | Success Metrics |

|---|---|---|---|

| Assessment | Identify use cases, evaluate ROI | 2–4 weeks | Use case prioritization is complete |

| Partnership | Select vendor, define requirements | 2–3 weeks | Contract signed, requirements documented |

| Data Collection | Gather & label training images | 4–8 weeks | Sufficient dataset collected |

| Pilot Deployment | Install the system, run parallel testing | 6–12 weeks | Accuracy targets met |

| Production Scale | Expand to additional lines | 3–6 months | ROI achieved, full deployment |

While this implementation roadmap addresses today’s deployment needs, computer vision technology continues evolving at a rapid pace. Understanding where the technology is heading helps you make strategic decisions about your investment with computer vision development companies and ensures your systems can adapt to future capabilities.

Get Expert Guidance on Computer Vision Implementation

Our AI consultants assess your manufacturing setup, identify high-impact use cases, and design a tailored roadmap for seamless computer vision adoption, ensuring faster ROI and smoother deployment.Future Trends in Computer Vision for Manufacturing

Computer vision technology is not static; it is rapidly evolving. Stay ahead of the curve by exploring these future trends, which will help you strategically prepare for the next generation of inspection capabilities.

1. AI model advancement

Newer architectures require less training data, process images faster, and generalize better to new situations. Few-shot learning recognizes new defect types from just a handful of examples, dramatically accelerating deployment for new products. Self-supervised learning enables models to improve continuously without manual labeling, reducing ongoing data collection costs.

2. Edge computing evolution

Next-generation processors enable sophisticated AI models to run locally on production floors, reducing latency and bandwidth requirements. Distributed systems will coordinate across multiple inspection stations, sharing learning and optimizing facility-wide quality. This enables real-time decision-making without cloud dependency while maintaining data security within manufacturing facilities.

3. Expanded 3D capabilities

Advanced 3D cameras capture detailed surface topology and measure complex geometries with improved accuracy and speed. Multimodal sensing combines 2D vision with 3D depth data, thermal imaging, and hyperspectral analysis to detect defects invisible to any single sensing method. This comprehensive approach provides the most complete quality assessment possible for complex manufacturing applications.

4. Increased accessibility

Cloud-based platforms reduce upfront costs by eliminating expensive on-premise infrastructure requirements, making computer vision affordable for mid-size manufacturers. Pre-trained models accelerate deployment by leveraging existing AI knowledge, while no-code tools enable quality engineers to configure inspection systems without programming expertise.

This democratization expands adoption beyond large enterprises to manufacturers of all sizes and budgets.

Streamline Your Manufacturing Operations with Custom Computer Vision Solution Development

Computer vision solutions for manufacturing deliver measurable quality improvements while reducing costs and eliminating recall risks. From defect detection to predictive maintenance, these systems provide the automated inspection capabilities that modern production demands.

At Space-O AI, we specialize in developing custom computer vision solutions for manufacturing operations. With 15+ years of proven expertise and 500+ successful AI projects, our experienced team understands the unique challenges you face, whether you’re addressing quality control issues, optimizing production efficiency, or preventing costly defects.

We guarantee 99.9% uptime with enterprise-grade security, delivering fully functional computer vision systems that integrate seamlessly with your existing infrastructure. Our solutions scale with your business growth and adapt to evolving production demands, ensuring long-term value and performance.

Let’s discuss how computer vision can transform your manufacturing quality control. Get in touch with us today to start building your solution with our experts.

Frequently Asked Questions on Manufacturing Computer Vision Solutions

How accurate are computer vision systems compared to human inspectors?

Computer vision systems achieve significantly higher accuracy than human inspectors for repetitive visual tasks. Human accuracy declines from fatigue and subjective judgment, while vision systems maintain consistent performance indefinitely.

Accuracy depends on proper design, adequate training data, and appropriate lighting. Well-implemented systems catch defects that inspectors consistently miss while reducing false positives that waste time in secondary inspection.

What’s the typical ROI timeline for computer vision implementation?

Most manufacturers achieve ROI relatively quickly through reduced scrap, rework, and labor costs. High-volume operations with significant quality costs see faster returns. ROI calculations should include avoided recalls, improved customer satisfaction, and competitive advantages.

Multiple applications spread development costs while accelerating returns, with systems delivering value for years through consistent quality improvement and process optimization.

Can computer vision systems work with our existing equipment and processes?

Yes, vision systems integrate without wholesale changes. Cameras mount near inspection points, processing happens via edge computers or cloud platforms, and integration uses standard interfaces.

Some applications benefit from minor modifications like improved lighting or additional inspection stations. AI consulting services assess infrastructure during planning to ensure smooth integration and minimal production disruption.

How much training data is required for effective defect detection?

Training requirements vary by complexity. Simple applications need hundreds of labeled images while complex inspections benefit from thousands of examples. Transfer learning and pre-trained models significantly reduce requirements.

Starting data collection early ensures sufficient training data when implementation begins. Synthetic data generation and data augmentation help when real-world examples are limited, particularly for rare defect types.

What maintenance do computer vision systems require?

Systems require minimal ongoing maintenance beyond regular camera and lighting cleaning based on environmental conditions. Software updates occur periodically to improve models and add features.

Recalibration may be necessary when products change significantly. Quality teams should monitor accuracy metrics and coordinate model retraining using recent production data. Most facilities assign responsibility to quality engineers who review system performance.

Can we implement computer vision without disrupting current production?

Yes, phased implementation minimizes disruption. Systems are initially deployed in shadow mode parallel to existing inspection without affecting production decisions. This validation phase confirms accuracy before going live.

Systems transition to active inspection during planned downtime or slower production periods. Some installations happen during off-shifts to avoid disrupting operations. The pilot approach proves systems before expanding.

Looking for Computer Vision Experts?

What to read next