Artificial intelligence is reshaping how modern supply chains operate. From demand forecasting and inventory planning to logistics, warehousing, and last-mile delivery, AI is helping businesses respond faster, reduce operational costs, and make smarter decisions backed by real-time data.

The shift is accelerating. According to Precedence Research, the global AI supply chain market is projected to grow from USD 9.94 billion in 2025 to USD 192.51 billion by 2034. With supply chains becoming more complex and disruptions becoming more frequent, companies are turning to AI to create more efficient, agile, and resilient operations.

AI-powered systems can analyze massive data sets, predict future demand, optimize stock levels, and improve delivery accuracy at a scale that is impossible with manual processes. This allows businesses to streamline workflows, minimize errors, and maintain consistent service levels even during unstable conditions.

As a result, AI is no longer a future technology for supply chain teams. It is now a practical, high-impact tool that supports every stage of the supply chain. In this guide, you will learn what AI in supply chain means, how it works, the top use cases, real-world examples, challenges to consider, and future trends.

Based on our experience as a trusted AI software development company, we have shared insights on how businesses can adopt AI successfully and create a smarter, data-driven supply chain strategy. Let’s get started.

AI in supply chain management refers to the use of advanced algorithms, machine learning, predictive analytics, and automation technologies to improve the way goods move from suppliers to customers. It enhances every stage of the supply chain by analyzing large volumes of data, identifying patterns, and making accurate predictions that help businesses plan better and operate more efficiently.

At its core, AI enables supply chain teams to shift from reactive decision-making to proactive, data-driven strategies.

Instead of relying on manual processes or historical trends alone, AI systems process real-time information from multiple sources such as sales data, market trends, inventory levels, supplier performance, and external risk indicators. This allows businesses to forecast demand, optimize stock, improve logistics, and reduce operational costs with higher precision.

AI-powered supply chain systems operate through three stages that transform raw data into actionable intelligence.

The system ingests data from multiple sources: ERP systems, IoT sensors, supplier databases, market feeds, weather data, and logistics platforms. This creates a unified dataset representing your entire supply chain ecosystem in one place for the first time.

Machine learning algorithms analyze the dataset to identify patterns, relationships, and anomalies that humans would miss. The system learns what “normal” looks like, recognizes warning signs of disruptions, and predicts future outcomes like demand shifts, equipment failures, or delays.

Based on patterns, AI generates real-time recommendations or automated decisions. Quality systems flag defects before shipping. Route optimization finds efficient paths. Inventory systems recommend reordering points. Risk monitoring alerts you to disruptions 3-5 days before impact.

Building these intelligent systems requires specialized expertise. Leading AI software development companies combine deep machine learning knowledge with supply chain domain understanding to create solutions tailored to your specific operational context.

Now that you know how AI operates, let’s look at what really matters: the measurable business results companies are achieving right now.

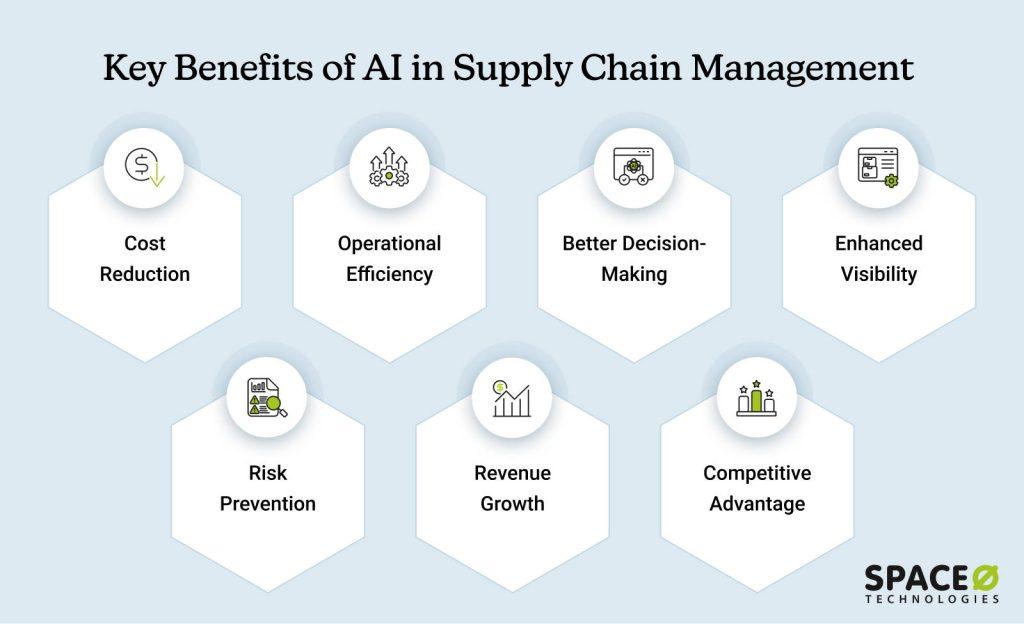

When companies deploy AI for supply chain operations, they don’t just improve metrics. They transform entire business models. Organizations see concrete improvements in cost, speed, quality, and competitiveness. Here are the benefits of AI in the supply chain in practice.

AI eliminates manual tasks through automation and optimizes logistics routing, inventory levels, and maintenance schedules. Companies reduce operational expenses by 15% to 35% across supply chain functions, directly improving margins and profitability.

AI processes millions of data points instantly, making real-time decisions that would take humans hours or days. Throughput increases, error rates drop, and systems operate continuously without fatigue or breaks, multiplying productivity per resource.

Real-time insights replace manual analysis. AI demand forecasting and risk alerts provide automatic recommendations. Supply chain leaders make faster, data-driven decisions with complete visibility instead of relying on incomplete information and intuition.

End-to-end supply chain visibility becomes possible for the first time. Track inventory, shipments, and supplier performance in real-time across your entire network. Identify bottlenecks and disruptions immediately instead of discovering problems after they cascade.

AI detects anomalies and predicts disruptions 3 to 5 days before they impact operations. Proactive alerts enable contingency planning. Supplier risks, demand shifts, and equipment failures are identified early, preventing costly crises and production shutdowns.

Better AI inventory management eliminates stockouts and lost sales. Faster delivery improves customer satisfaction and repeat orders. Quality improvements reduce returns and warranty costs. These benefits combine to directly increase revenue while reducing costs.

Early adopters build internal expertise and data assets that compound over time. Systems improve continuously, creating widening gaps between AI leaders and followers. First-mover advantage in your industry becomes increasingly difficult for competitors to overcome.

Now you know what’s possible. The question is: where do you start? Seven proven use cases show exactly where AI delivers the highest impact in supply chain operations, and which problems your competitors might already be solving.

Transform Your Supply Chain with Custom AI Solutions

Modernize forecasting, logistics, inventory, and operations with AI solutions built specifically for your business. Work with Space-O AI to design, develop, and deploy high-impact supply chain systems.

Real-world AI in supply chain use cases demonstrates how companies capture competitive advantages today. Whether your challenge is inventory management, logistics efficiency, or risk mitigation, AI has a solution already proven in production environments.

Traditional demand forecasting misses a majority of demand fluctuations, resulting in either excess inventory tying up capital or stockouts losing sales. Manual inventory management is reactive, not predictive. The cost impacts everything: warehouse space, carrying costs, lost revenue, and customer satisfaction all suffer simultaneously.

This is why leading retailers have shifted to demand prediction. When you hire AI developers with supply chain expertise, they build systems that know what customers want before they know it themselves.

Manual route planning produces inefficient paths. Real-time traffic, weather, and order changes aren’t factored in. Drivers follow predetermined routes created hours earlier, resulting in unnecessary miles, excessive fuel consumption, missed delivery windows, and frustrated customers demanding faster service.

The companies winning in logistics aren’t just faster drivers. They’re using technology to eliminate inefficiency before it starts.

Equipment failures disrupt operations catastrophically. Production lines halt. Warehouse conveyors stop. Refrigeration units fail. Companies manage equipment reactively: run until failure, then repair. Downtime is unpredictable, replacement parts aren’t on hand, and emergency repairs cost significantly more than planned maintenance.

The shift from reactive maintenance to predictive maintenance isn’t just about cost savings. It’s about operational certainty and eliminating the unpredictability that has plagued supply chains for decades.

Manual quality inspection relies on human attention over repetitive tasks. Inspectors tire, attention lapses, and subtle defects escape detection. Error rates around 10-15% mean defective products reach customers, causing returns, complaints, and brand reputation damage that compounds over time.

Quality isn’t just about customer satisfaction anymore. It’s about brand survival. AI ensures quality control becomes a competitive advantage rather than a cost center.

Manual picking and sorting operations are labor-intensive, error-prone, and difficult to scale. Finding products in massive warehouses takes time. Picking errors around 5% mean one in twenty items is incorrect. These operations represent significant labor costs and create fulfillment bottlenecks.

Warehouse automation is no longer a luxury for mega-retailers. It’s becoming table stakes for any company competing on speed and accuracy in fulfillment. Integrated computer vision in supply chain systems guides robots through precise picking operations, making warehouse automation seamless and highly efficient.

Supply chain disruptions often start with supplier failures. Financial troubles, geopolitical events, natural disasters, and regulatory changes all impact suppliers silently. Without visibility, companies discover problems after they impact production. Traditional supplier selection relies on historical performance and price alone, missing emerging risks entirely.

Supplier risk management used to be a reactive crisis response. AI transforms it into strategic foresight that prevents crises from happening in the first place.

Fleet management involves complex optimization. Hundreds or thousands of vehicles make thousands of daily trips. Each trip has a starting point, destination, and timing requirement. Optimizing across all variables manually is impossible. Vehicles take inefficient routes, some are underutilized, while others are overloaded, and accident rates include preventable incidents.

Fleet optimization goes beyond saving fuel. It’s about extracting maximum productivity from every asset while keeping drivers safe and operations predictable.

Supply chain disruptions start small. A shipment arrives one day late. Inventory counts don’t match by a few units. A supplier misses a minor specification. Individually, these seem minor, but they cascade into major problems if not caught early. Detecting which anomalies matter among thousands of daily transactions is impossible manually.

Early detection isn’t just about avoiding problems. It’s about giving your team the breathing room to make smart decisions instead of emergency ones.

Now you understand what’s possible. The question shifts: what obstacles stand between you and actually implementing these solutions? The answer is important. Because knowing the challenges upfront means you can plan for them, budget for them, and overcome them systematically.

Build a Smarter, Faster, More Predictive Supply Chain

Leverage AI-powered forecasting, optimization, and automation to reduce costs and boost efficiency. Our team helps you turn complex supply chain challenges into scalable solutions.

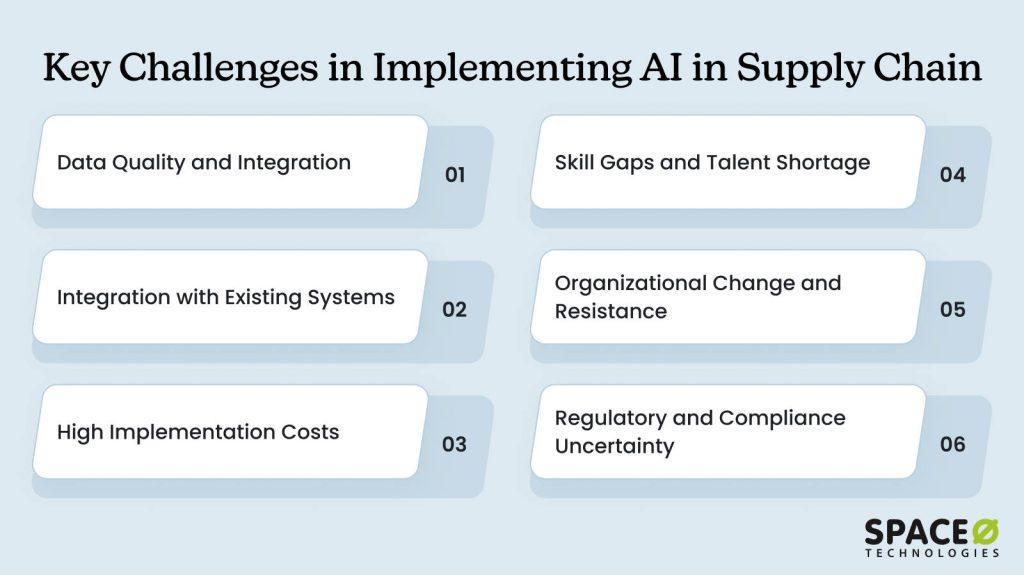

Implementing artificial intelligence in supply chain management comes with real obstacles. Understanding these challenges upfront helps you plan effectively and avoid costly mistakes. This section covers the most common barriers and provides practical solutions to overcome them systematically.

Your legacy systems store data in incompatible formats across disconnected silos, making unified access difficult. Real-time integration with existing ERP systems is complex, and before meaningful artificial intelligence and supply chain implementation begins, cleaning and standardizing data requires substantial upfront effort and investment.

Legacy ERP and warehouse systems lack API readiness for modern integration, making custom connections expensive and time-consuming. Implementation downtime disrupts operations while teams resist changes to familiar systems. These integration barriers delay deployment and increase project costs significantly.

AI platform licensing starts at $50,000 to $200,000, while hardware infrastructure and data preparation add substantial costs. Integration services, ongoing maintenance, and optimization accumulate into significant annual expenses. Budget constraints limit adoption across small and medium-sized organizations, especially.

Few supply chain professionals understand AI and machine learning deeply enough to lead implementation. Data scientists are expensive to hire and difficult to retain internally. Training existing staff takes significant time, and relying entirely on external vendors creates dependency risks.

Employees fear job loss, especially in warehouse and logistics roles that manage routine tasks. Skepticism about AI reliability slows adoption while teams resist leaving comfortable existing processes. Change fatigue from previous initiatives compounds resistance throughout the organization.

Regulations around AI use are evolving without clear universal pathways for implementation. Data privacy requirements under GDPR and CCPA impose strict limitations, while industry-specific compliance rules vary. Liability questions remain unresolved when AI recommendations prove incorrect.

Knowing the obstacles is half the battle. The other half is executing with a proven process that accounts for these realities. Here’s the step-by-step implementation roadmap that turns challenges into competitive advantages.

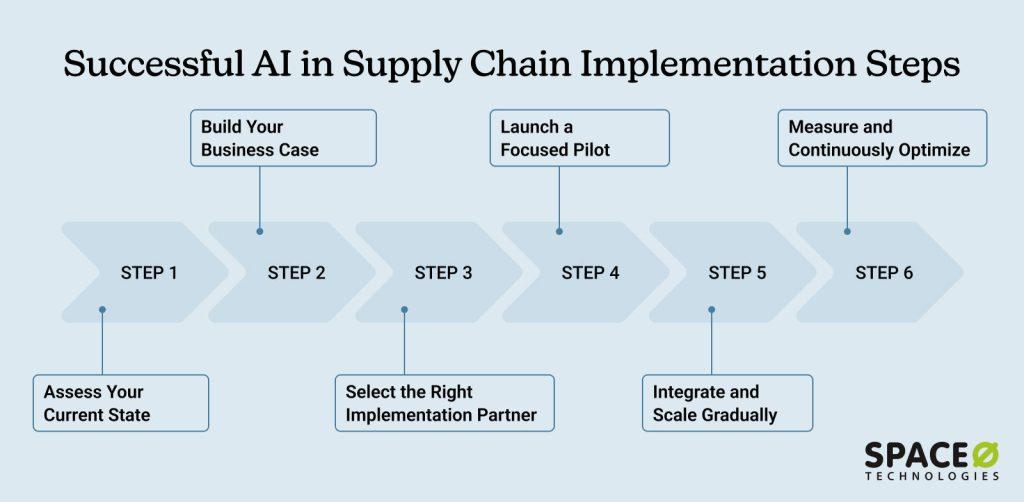

Implementing AI in supply chain management doesn’t have to be overwhelming. By following a structured approach, you can move from planning to operational results systematically. This roadmap guides you through each phase, from identifying opportunities to measuring success. Companies that follow this process reduce implementation risk while accelerating time-to-value.

What to do:

By understanding where inefficiencies exist, you can target AI for supply chain optimization in the areas with the highest potential ROI. You walk away with a prioritized list of opportunities ranked by impact and implementation complexity.

What to do:

A strong business case secures executive buy-in and implementation funding. You gain alignment on expectations, investment, and measurable goals before moving forward.

What to do:

Selecting the right partner minimizes risk and accelerates execution. You start with a clearly defined contract outlining deliverables, timelines, and support requirements.

What to do:

A controlled pilot proves the value, validates assumptions, and builds internal confidence before full-scale rollout. You end this phase with proven results and clear learnings.

What to do:

Scaling in phases reduces operational disruption and ensures adoption. You expand into additional areas while maintaining performance stability.

What to do:

Ongoing optimization ensures ROI continues growing over time. You create a continuous improvement loop with documented gains and a roadmap for the next phase of innovation.

Partner with Experts in AI-Driven Supply Chain Development

From demand planning models to intelligent logistics systems, we create custom AI solutions that align with your goals. Start your supply chain transformation with Space-O AI.

The gap between AI leaders and followers in supply chain management is widening fast. Companies implementing AI for supply chain management today are capturing advantages that will persist for years.

Understanding the technology is step one. Executing it successfully is everything. Artificial intelligence in supply chain management requires more than software. It demands a partner who speaks both machine learning and supply chain language.

Space-O AI has spent 15+ years building custom AI solutions for supply chain and logistics that actually work. Our 80+ specialists have delivered 500+ successful projects across manufacturing, retail, and logistics. We don’t build one-size-fits-all tools. We build solutions aligned with your specific operational challenges, whether that’s demand forecasting, warehouse automation, or risk management.

Explore our portfolio to see how we’ve transformed companies across industries through intelligent, scalable AI systems.

AI Receptionist Development: Welco

A USA-based entrepreneur needed to automate front desk operations and manage customer calls 24/7. Space-O built Welco using NLP and voice technology for seamless call handling and appointment scheduling. Result: 67% reduction in missed inquiries, enabling businesses to deliver consistent support without expanding staff.

Moov AI: Product Recommendation Chatbot

In just 22 days, our team delivered Moov AI to Moov Store, Saudi Arabia’s leading eCommerce platform. Using OpenAI technology and vector embeddings, the chatbot generates personalized product recommendations. Result: faster checkouts, increased customer satisfaction, and significantly improved conversion rates through intelligent product matching.

AI Product Recommendation System: Clime

Businesses struggle to match customers with the right products at scale. We built this AI solution for our client that analyzes purchase history, behavior patterns, and preferences to deliver personalized recommendations automatically. Result: higher conversion rates, increased repeat purchases, and improved customer experience through data-driven intelligent suggestions.

Today, the real question isn’t whether to invest in AI. It’s how quickly you can deploy it effectively. Ready to explore which use cases matter most for your supply chain? Get in touch with our experts today for a free strategy session.

Implementation ranges from $50,000-$100,000 for focused pilots to $200,000-$500,000+ for full deployments. The key is prioritizing high-impact use cases. With AI for supply chain optimization, most organizations achieve ROI within 12-18 months through labor savings, error reduction, and improved efficiency. Many see positive cash flow within 6-9 months by starting with quick-win applications like route optimization or demand forecasting.

Pilot projects typically require 8-16 weeks from planning to operation. Full deployments span 6-12 months, including assessment, vendor selection, development, integration, and training. Timeline depends on data readiness and system complexity. Starting with one high-impact operational area accelerates results. Many companies see tangible benefits within 3-4 months when the data is clean and the scope is focused.

Identify your biggest operational challenge: inventory imbalances, logistics inefficiency, quality issues, or equipment failures. Compare against AI in supply chain examples to find proven implementations. Demand forecasting and warehouse automation typically deliver the fastest returns. Route optimization cuts fuel costs immediately. Success in one area builds organizational confidence and expertise for broader scaling.

Data fragmentation is manageable but requires upfront investment. Start by auditing data quality, identifying incompatible formats, and establishing governance standards. Don’t try to perfect everything; begin with high-quality pilot datasets in one area to prove value. This builds support for broader data initiatives. Poor data quality is the primary barrier to AI in supply chain and logistics success, so data preparation before deployment is essential.

No. AI in supply chain and logistics eliminates repetitive manual work, data entry, counting, routine exception handling, freeing teams for strategic decisions and relationship management. Employees focus on complex supplier negotiations, exception handling, and continuous improvement. Organizations report higher job satisfaction as tedious tasks disappear. Frame it as an augmentation, involve teams early, and demonstrate quick wins through pilots.

Yes. Modern solutions integrate with legacy ERP and warehouse systems through APIs and middleware. Cloud-based platforms generally offer easier integration than on-premise options. Experienced implementation partners bridge old and new technology through phased approaches. Select AI software development companies with proven legacy integration experience to avoid operational disruption during deployment.

Build AI-Powered Supply Chain Solutions